Specialized & General Milling

Ideal for Milling Heat Exchangers

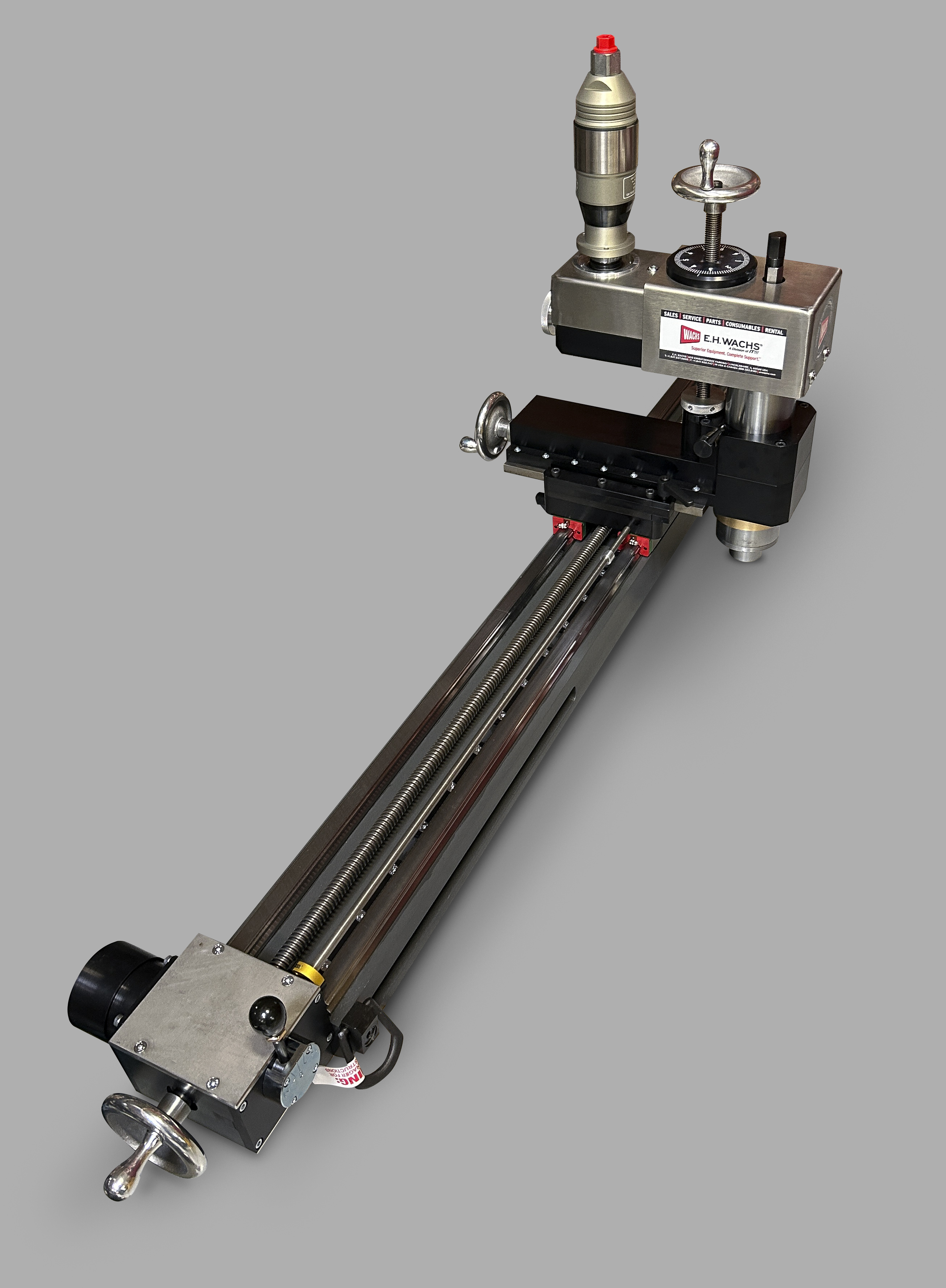

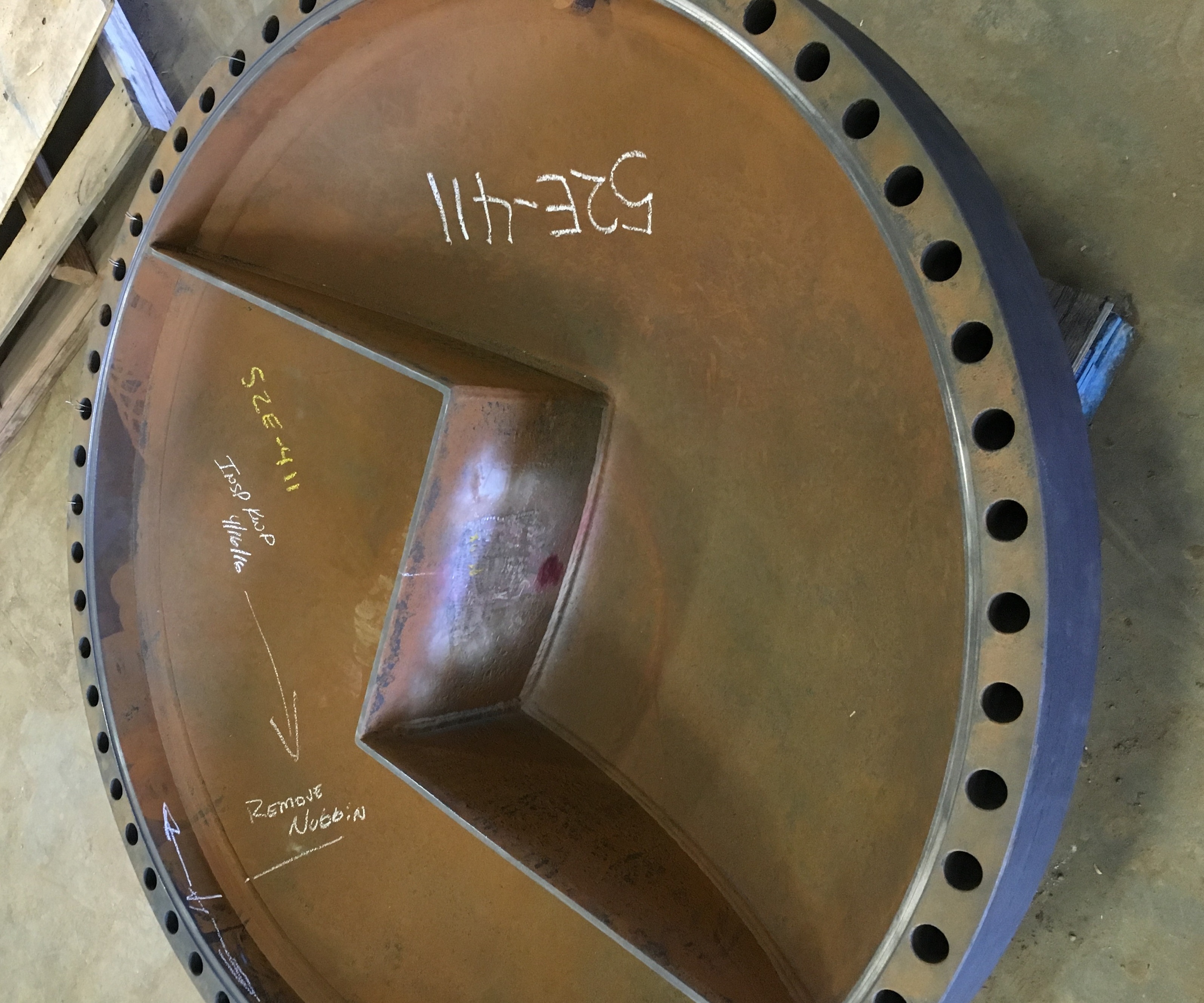

Wachs Exchanger Mill is a precision machine tool designed for specialized machining of exchanger baffle plates, pass partitions and pass grooves on heat exchangers, as well as general-purpose 3-axis milling. Available in three different travel length models, 4 foot (48 inches), 6 foot (72 inches), and 8 foot (96 inches), it’s designed to interface with Wachs DynaPrep Modular Design Split Frame family. Wachs portable exchanger mill is ideal for surface milling of plates and partitions to the flange plane during an exchanger refurbishing, as well as traditional 3-axis rail linear milling without the MDSF. It features full-length t-style clamping channels on the rail bottom, offering superb clamping flexibility when used for general-purpose milling.

Unlike ordinary mills, it features unique side channels for mounting to Wachs MSDF split frames. This allows the operator to perform flange facing utilizing an MDSF flange facer accessory (FFR or FFC), then mount the exchanger mill to the MDSF. The MDSF then serves as the rotating platform for the exchanger mill, allowing precise positioning of the mill for multiple plate angles. This eliminates the need for indicating and dialing in multiple tools to the surface plane and plate angles.

Wachs Exchange Mill is available in your choice of pneumatic or electric drive. For more information on purchase or rental options, contact your local Wachs representative.

STANDARD FEATURES

- Mountable rail (48", 72", and 96" travel lengths available).

- Pneumatic or electric drive options.

- Bottom t-style full-length mounting channel for mounting versatility.

- Two table mounting clamps attach the rail directly to the exchanger flange.

- Furnished mounting clamps can be positioned anywhere along the rail.

- Side mounting slots attach the rail to the Wachs MSDF split frame, or to alternate fixtures.

- Toolless clamp system for air motor mounting.

- Lifting rings positioned at each rail end.

- Industry standard R8 spindle uses commercially available tooling.

- Industry standard ¾” spindle collet included.

- Rigid but lightweight rail delivers smooth and consistent performance.

- Wooden shipping and storage case included.

OPTIONAL EQUIPMENT

- MDSF handwheel pinion assembly for manually positioning the mill on the exchanger.

- Factory modification of MSDF split frame toe clamp mounting holes when used as an exchanger mill platform may be required. Contact your local Wachs representative for details.

SPECIFICATIONS

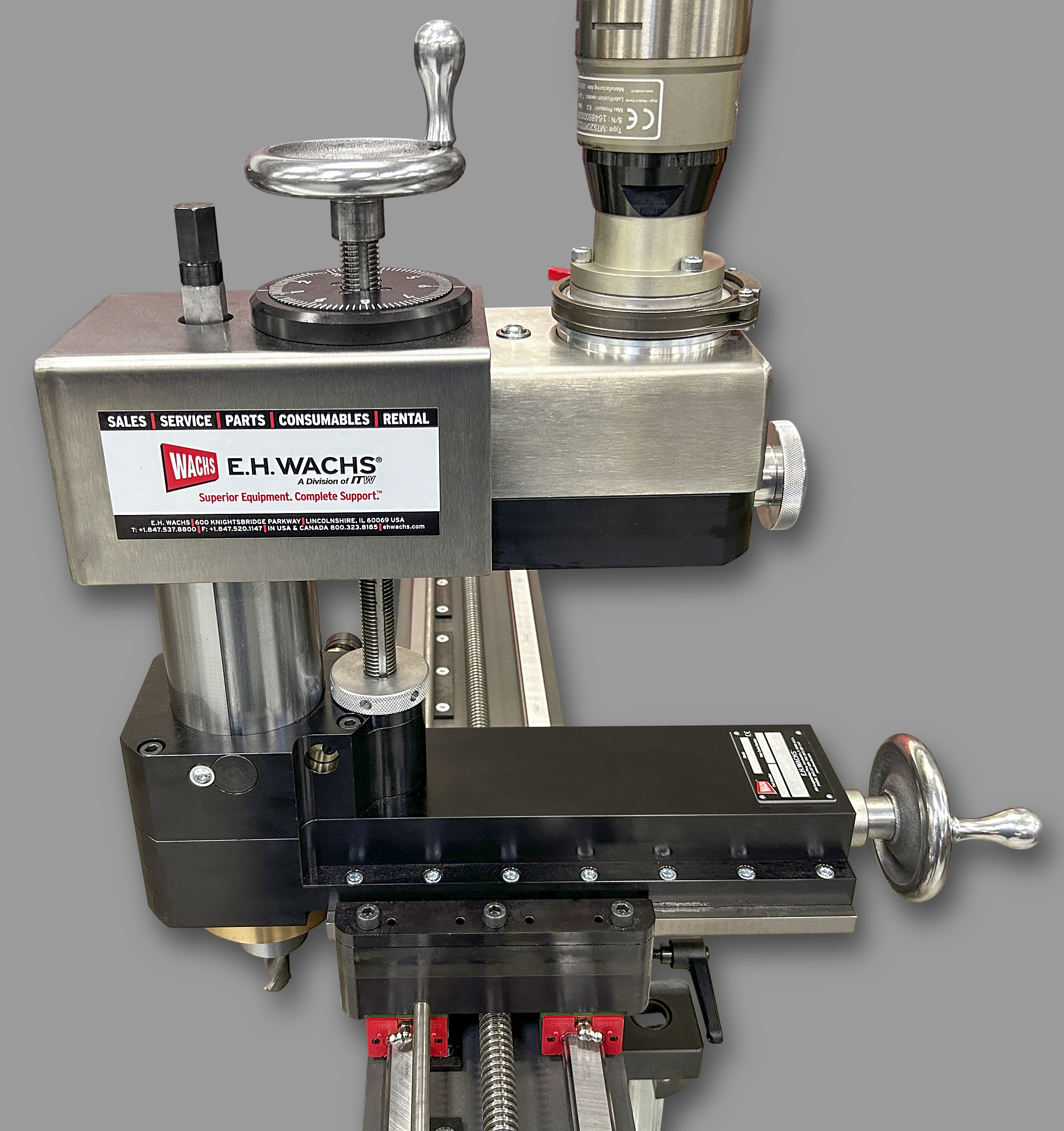

- Spindle end mill drive with air motor and speed control, manual cutting depth adjustment, and manual y-axis (offset from rail) adjustment.

- Reversible cutting feed drive mechanism (x-axis) with air motor, speed control, and travel direction control.

- Removeable table mounting clamps for mounting the mill to flanges or to alternative mounting fixture.

CONTROLS

- Feed (x axis) handwheel - for rapid positioning along rail.

- Feed (x axis) gearbox with rail travel direction control.

- Tool positioning handwheel (y axis) 90º degrees to rail travel.

- Spindle plunge handwheel (z axis) with easy-to-read depth indicator dial.

- Feed drive speed control and shut-off lever.

- Spindle drive speed control and shut-off lever.

- User positionable x-axis travel stops.